Southwestern College Info Tech Building

The Information Technology Building (ITB) is on the east side of Southwestern College in Chula Vista, CA. The project is 16,400 square feet and includes offices, a classroom, data center, network spaces, and a help desk. Following the campus’ rich tradition of exposed concrete, the most striking architectural feature of the ITB are 20 ft tall tilt-up walls along the north and east facades. The “unique” exterior finishes consist of varying panel thickness laid out on the walls in a random pattern of both size and finish.

During the preconstruction process most job issues related to schedule, specifications, budget were addressed. Site logistics was the only unknown as the exact grade of the area surrounding the building was an ever evolving issue for the duration of our work. Remedial grading within the jobsite was addressed a few days prior to the lifting of the panels to insure we could safely hoist the panels into place. Even with the remedial grading, one panel could not be picked due to a calculation error by the crane company. Approval to walk the crane onto the slab had to be obtained to lift the last panel with load cribbing and steel plates being used for weight distribution measures.

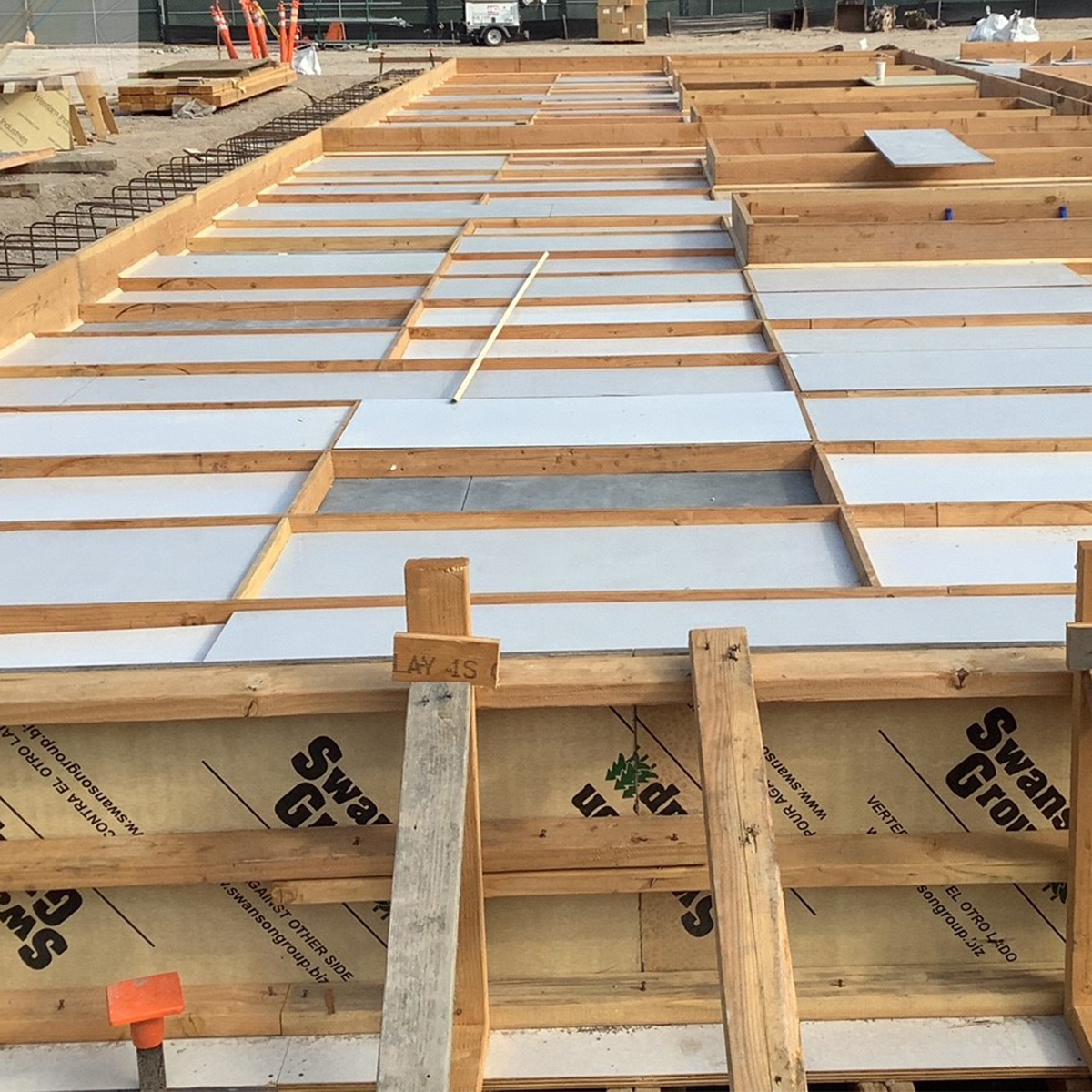

Typical panel “sections” on the walls are 2 ft. wide by 4 ft. 9 in. tall with reveals separating each adjacent section from the other with thicknesses ranging from 8 in. to 11 in. Each section would eventually receive either a smooth, light sandblast or heavy sandblast texture as the final finish application. To begin, sections with the smooth finish were covered while the first round of sandblasting was applied. Then the sections receiving the lighter finish were covered while the rest of the sections received a second round of sandblasting to create a heavier finish appearance. To accentuate the different thicknesses within each panel, reveals up to 3 in. tall (deep) separated each individual section. To ensure perfect reveal joints, all cuts at joints and intersections of reveals were mitered to an exact fit.

Quality control was a top priority on this project to deliver the client’s desired outcome. Craftsmen took extra care not to leave hammer marks on the plywood and to avoid uneven plywood seams. Place and finish teams also took extra care to ensure all panels were clear of debris before and during concrete placement. Table saws were used to back-cut a 22-degree angle on the HDO plywood form at each joint to ensure a tight seal and quality product after stripping.

Along with the critical information technology services which will be housed in this building, the tilt-up walls raise the bar for future concrete work on a campus already teaming with architectural concrete. This unique finish pushes the boundaries of what is architecturally possible with concrete and the look couldn’t have been accomplished quickly and economically without the use of tilt-up concrete construction.

Location: Chula Vista, CA

Market Sector: Education

Levels: One level above grade.

Gross Sq. Ft.: 16,480gsf

Complete: December 2021

Client: Southwestern College

Architect: Gensler

Engineer: Miyamoto International

Awards: Tilt-Up Concrete Association – Outstanding Achievement Award, Education Category