Ivy Station Wins ACI Award for Outstanding Performance in Design and Engineering

The American Concrete Institute (ACI) recently awarded the Ivy Station project the award for Outstanding Performance in Design and Engineering.

The American Concrete Institute (ACI) recently awarded the Ivy Station project the award for Outstanding Performance in Design and Engineering.

The American Concrete Institute (ACI) gave the 2020 “Decorative Uses of Concrete Construction” award to the Linea Apartments in Los Angeles, CA.

The Entrada Creative Office in Culver City, CA is truly a unique structure combining state-of-the-art design with cutting edge engineering. The building is 13 levels tall including the roof with six levels of commercial office space above six levels of parking, one of which is below grade. The podium level is dubbed the “Sky Deck” and features a 14,000sf landscaped amenities space with a fitness center, conference room and open space for all tenants to enjoy. The 815,000gsf building along Centinela Avenue is clad in glass and metal screens with exposed concrete interior columns and walls. Drivers along I-405 will be drawn to the open-air private balconies stepping up the commercial levels on either side of the building. The rectangular office levels are rotated with respect to the lower parking floors creating a substantial corner cantilever at the west face of the building making a strong architectural statement. The load of the cantilever deck is carried by a massive structural post-tensioned upturn beam located on the West edge of the roof.

Beneath the surface the Entrada development began with three mat foundation pours averaging 4,500CY. Two of the mass concrete pours at the elevator cores required a thermal control plan to ensure temperatures did not exceed 165 degrees during placement. Parking levels hold 1,044 stalls and 695CY of shotcrete walls line the perimeter of the basement.

Elevated decks are concrete voided slabs or “bubble decks” supported by high-strength cast-in-place columns and walls. Voids are created using hollow spheres made of recycled plastic and arranged in 8’x10’ wire mesh grid prefabricated offsite. Once on site the grids are placed on a layer of two-way rebar installed on the plywood deck with another layer of reinforcing on top. Deck pours begin by placing the first 4” to 6” of readymix to secure the voids in place before the balance of the slab is poured. Elevated decks ranged between 16” to 20” with typical levels at 18” thick.

The flat plate, bubble deck system allowed architects to maximize floor space in the building with a typical bay measuring 30’x45’. Flat decks also enhanced production flow by eliminating beams, drop caps, depressions and hanging form build up. On average Largo poured 11,000sf of deck every other day during the elevated slab duration of the project.

Overall, the voided slab construction reduced the weight of the structure nearly 30% in comparison to conventional methods of waffle slab or post-tensioned decks. This measure not only limited the seismic forces and foundation loads but also reduced the environmental impact of the project with significantly less material to transport and a faster schedule. The company supplying the voids was BubbleDeck North America.

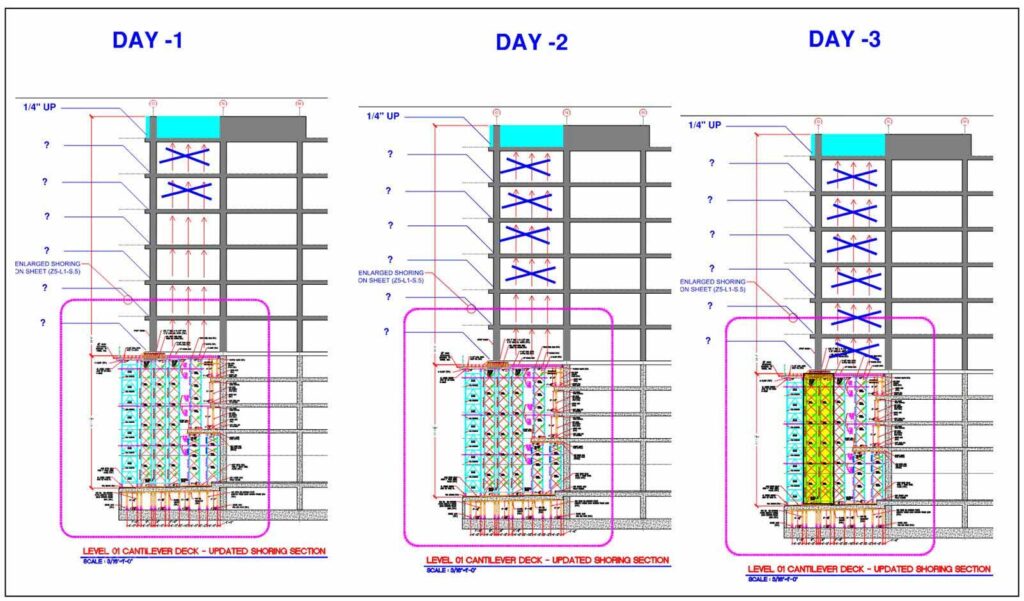

The corner cantilever at the Sky Deck level required shoring from street level to remain in place until the 3’ wide by 10’ tall upturn beam on the roof deck was poured and stressed. All six stories of office space and the roof are suspended at this corner from this same upturn beam on the roof. The corner columns of the cantilever have continuous reinforcing from the first commercial level to the roof. This feature required the shoring removal process to be reversed with the upper levels being stripped first while checking for deflection throughout the process.

Largo poured over 47,000CY in the structure over 11 months. General contractor KRPS, Gensler architects and Saiful Bouquet structural engineers aim to have the project complete in the first quarter of 2021 making it the first, large scale structural bubble deck system on the West Coast.

Largo topped out at the 4 Diller project in Redwood City, CA this month! The 555,736gsf building is located in the heart of Silicon Valley and 35 of the 350 total units are designated as for affordable housing.

Click here for more information.

1066 Market

The Market street development will hold 303 units and 97 parking stalls spread across 3 levels below grade and 16 levels above. Working with general contractor Swinerton Builders, Solomon Cordwell Buenz architects and Nishkian Menninger structural engineers, Largo expects to top our during the summer of 2019.

[print_gllr id=7404]

875 California

A couple miles north, the 875 California development is also being constructed with the same general contractor and structural engineer, with BDE Architecture. The building will house 44 units above 48 parking stalls on 100,000gsf. The structure will be 2 levels below grade and 8 levels above and is expected to top out during the summer of 2019.

[print_gllr id=7405]

Largo topped out at the 953 N. Sycamore project last week with the CIM Group in Los Angeles, CA. The development is two levels below grade and nine levels above with only the top three floors allocated to occupied space. The remaining levels of the 214,573gsf development are dedicated for parking a total of 418 cars. Designed by Lorcan O’Herlihy Architects and the BPA Group as structural engineers, the building twists away from the street as it moves up causing some of the cantilevered formwork and shoring to rest on the roof of the adjacent building.

Office Building Photos

[print_gllr id=5083]

[su_youtube_advanced url=”https://youtu.be/njzKanGV6n0″ height=”420″ rel=”no”]

Two blocks to the east along Romaine St., Parking Structure C Topped out for The Lot Studios around the same time. This eight level, long-span parking structure was completed in the design-build project delivery format. Largo Concrete was the general contractor self-performing the concrete place and finish and unit masonry scopes of work. The structure totals 140,790gsf and holds 398 total stalls with two elevators and two staircases. Working for the same CIM Group, the parking structure was designed by Parking Design Solutions and Ficcadenti Waggoner and Castle Structural Engineers and is scheduled to open early summer 2018.

Parking Structure Photos

[print_gllr id=6757]

Structural concrete at the new City Hall and Port Building in Long Beach, CA.

[su_youtube_advanced url=”https://youtu.be/_WbajxoyL0c” height=”340″ rel=”no”]

1,500CY mat foundation pour at the Thompson Hotel on Wilcox Avenue in Los Angeles, CA.

[su_youtube_advanced url=”https://youtu.be/SPVeu9eciUA” height=”340″ rel=”no”]

[print_gllr id=7160]

Congratulations to the Culver City Creative (C3) team who helped us bring home the Charles Pankow, Jr. Award for “Outstanding Achievement and Excellence in Concrete Construction”! The annual award is given by the American Concrete Institute and recognizes outstanding and innovative use of concrete in construction.

About the Project:

Largo topped out at the Culver City Creative (C3) Office Tower and Parking Structure in January of 2017 with general contractor KPRS. Designed by Gensler and Saiful Bouquet, the commercial building stands seven levels tall with four mezzanine levels totaling 321,000gsf and is seeking a LEED Gold Certification. All the building concrete received an architectural finish and will remain exposed once complete. Typical levels are 14’ tall while decks with intermediate levels range from 22’ to 26’ between level seven and the roof. Six private balconies on the east and west sides of the building cantilever 11’6” out and are accessible through the large operable glass façade. Other unique structural elements include columns so large they are practically walls, aka ‘walumns’, and ring beams on the perimeter of the building at the mezzanine levels. The high-volume ceilings and available raw space allow 33,800sf decks to be easily expanded to 45,000sf with vertical and horizontal expansion options.

[print_gllr id=3966]

Access to the adjacent nine level, long-span parking structure is provided through two pedestrian bridges on the third and fifth levels allowing for private access to upper level offices. Designed by Parking Design Associates and Miyamoto International, this shear wall structure is two bays wide and will house 990 stalls across 326,741gsf. The pedestrian bridges connect to the structure on levels five and eight with the end-to-end helix structure providing 30 electric vehicle stalls and 50 bicycle spaces. The exterior features semi-opaque colored panels attached to the shear walls which refract sunlight back onto the structure creating an ever-changing façade throughout the day. All concrete on the parking structure remains exposed, including the elevator lobby. Largo poured 18,805CY of concrete in the office building and 10,874CY in the parking structure. The adjacent creative campus had to remain operational during construction and the biggest challenges came from protecting the existing parking structure and the cars inside of it.

[print_gllr id=3887]

The Multidisciplinary Research Building topped-out this week at the University of California, Riverside. Working with general contractor Hensel Phelps, Smith Group JJR Architecture and Saiful Bouquet Structural Engineers the building a basement with five levels above grade for a total of 179,540gsf. Located between the Dept. of Bioengineering and the Student Recreation Center, the main atrium entrance spans four levels off Aberdeen Drive. The facility will house research laboratories, support facilities, a vivarium along with faculty and academic support space. The building is scheduled to be open in the Fall of 2018 and is seeking the Leadership in Energy and Environmental Design (LEED) Platinum Certification.

[print_gllr id=5238]

Focusing on the integration of life sciences, chemical sciences, medicine and engineering, this will be the fourth project Largo has completed on university campuses with the same collaborative STEM goal: The Chapman University Science and Technology Building in Orange, the USC Michelson Center for Convergent BioSciences in Los Angeles and the Stanford BioEngineering/ChemEngineering Building.